Marble Inlay Work, an

introduction & history

What is Inlay Art?

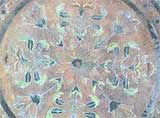

One of the most attractive work of art that comes from marble is

"Marble

Inlay" work. It is the same work that adorns the Taj

Mahal and

other Mughal monuments.

It is a closely protected

traditional art and only a few expert exponents are available

today. The delicate process involves cutting and engraving marble

shapes manually. To start with, a predefined pattern e.g., floral

design or geometrical design is engraved on the marble slab. Small

pieces of marble of different shades are cut delicately to fit in

these grooves precisely. These small pieces are then slipped in

the grooves. Apart from marble, many other materials can also be

used.

History of Inlay Art:

Inlay work on delicate precious stone began in the workshops

of Florence in Italy around the end of the 16th century. This was

known as PIETRA DURA.(Pietra= Stone, Dura= Hard) The Italians

had created a classic artistic form and held a monopoly over it.

From 1630 onwards pietra dura appeared on moveable, small objects

as decorative panels, with bird and flower motifs, suitable for

cabinet fronts and table tops. Some of these soon reached the Mughals in the form of presents.

Of all the Mughal Emperors, Shah Jahan was the greatest

patron of architecture in India. For him no

amount of money or time was too much to create enduring,

everlasting architectural beauty and through it be remembered

always. It is in his buildings that one feels most compelled to

make the connection between Mughal art and pietra dura. The Taj

Mahal, the cenotaphs of the Emperor and his wife, the main floor

and the surrounding marble railings bear very close resemblances

to the pietra dura form.

Process of Inlay Art:

Bases:

We mostly use two types of bases, White Marble and Black Stone (Kadappa

this is Sandstone).

We can also use other colored bases such as Green Marble, as per

buyerಥquirement. Inlay on White Marble gives a Royal touch

where as Black Stone gives a very attractive look.

Types of bases we used: 1) White Marble (Makrana, Rajasthan

india)

2) Creama Marble (Italy)

Inlay natural stones:

A design, be it a floral or geometrical motif is cut out on a

brass sheet. This is then placed on marble, drawn and then the

marble is carved out. Slices of Colored stones, which have in

the meantime been shaped and polished, are then laid into the

marble with adhesive.

There are almost 30 types of color stones available. Sometimes a

heat treatment is given to particular stone to get a shading

effect, e.g. heating Jaisalmer (Yellow) stone to get a red

color.

Types of natural stones normally used for inlay :

1) White Jasper

2) Chocolate Stone

3) Green Marble

4) Sang-a- Mariam

5) Tiger Stone

6) Red Jasper

7)Lapis

8) Green Aventurine

9) Brown Bidasar

10) Black Onyx

11) Yellow Aventurine

12) Green Bidasar

13) Yellow Bidasar

14) Cobra Stone

15) Malachite

16) Ruby

17) Jaiselmer Red (Heated)

18) Dark Green Bidasar

19) Creama Marble

20) Jaiselmer Yellow

21) Alikantak

22) Green Laventure

23) Torques (Firoza)

24) Amethyst

All of these are natural stones, we do not prefer Synthetic

stones, but can be used according to buyerಥquirement.

Polish:

When Inlay work has been completed and it has dried, the surface

and edges are polished to give a shiny finish. The polish work

is being done by stone bar so as to give a long lasting shine.

Packing:

After the Table Tops being polished now they are ready for

packing. We prepare wooden pallets (Keeping safety in mind).

Table tops are being covered by thermacol sheets from all sides

including corners also.

|

|